Why Carbon Footprint Management is Becoming a Business Imperative

Manufacturers are at the forefront of the global effort to reduce carbon emissions. What was once a voluntary sustainability initiative has evolved into a non-negotiable business requirement. Today, managing carbon emissions is not optional—it is a strategic necessity that directly influences market access, brand equity, and long-term business resilience.

Market Access: Staying Competitive in a Changing Regulatory Landscape

Global regulatory frameworks are tightening rapidly. Governments are introducing more stringent carbon disclosure requirements and implementing mechanisms such as emissions trading schemes and carbon taxes—developments that directly impact manufacturing operations and cost structures. In jurisdictions such as the EU and the U.S., new legislation is expanding mandatory carbon reporting to a broader range of companies, including those deep within manufacturing supply chains. Failure to comply can lead to financial penalties, restricted market access, and exclusion from supply chains that prioritize sustainability.

In India, the Business Responsibility and Sustainability Reporting (BRSR) framework now mandates top listed companies to disclose detailed data on carbon emissions and climate actions, with requirements expanding to value chain disclosures from FY 2025-26. This is driving broader compliance across Indian manufacturing supply chains.

Similarly, ASEAN is advancing regional carbon regulations through the ASEAN Common Carbon Framework (ACCF), which aims to harmonize carbon reporting standards and facilitate cross-border carbon credit trading. These initiatives are making robust carbon management essential for manufacturers operating in or exporting to these regions

Proactive manufacturers that manage their carbon footprint are better equipped to:

- Comply with dynamic regulations and avoid costly penalties.

- Tap into new markets and appeal to carbon-conscious customers.

- Maintain and grow their role in global supply chains, as leading OEMs and brands increasingly require emissions transparency from suppliers.

Brand Reputation: Building Trust and Market Differentiation

Sustainability has become a core driver of brand value. Manufacturers that prioritize carbon management are perceived as responsible, future-ready, and trustworthy by customers, investors, and stakeholders alike. These reputational advantages yield measurable business benefits:

- Stronger customer loyalty and willingness to pay a premium for sustainable offerings.

- Increased appeal to investors focused on Environmental, Social, and Governance (ESG) performance.

- Enhanced ability to attract and retain top talent, particularly among younger, purpose-driven professionals.

Transparent carbon accounting and consistent reporting also help mitigate reputational risks such as greenwashing or greenhushing. Companies that communicate clear sustainability goals and demonstrate progress are more likely to gain industry recognition, positive media attention, and stakeholder goodwill.

Long-Term Business Success: Driving Efficiency and Resilience

Effective carbon footprint management enhances operational efficiency and supports long-term profitability. Through process optimization, adoption of clean technologies, and a transition to renewable energy, manufacturers can:

- Realize significant cost savings from reduced energy use and waste.

- Hedge against risks tied to carbon price volatility and supply chain disruptions.

- Position themselves for regulatory resilience and shifting market expectations.

For instance, companies that have shifted to low-carbon materials and fostered supply chain collaboration have not only reduced emissions but also lowered material costs. Strategic sustainability investments often deliver long-term value that far exceeds their initial expenditure—making carbon management a sound financial decision, not just an ethical one.

Conclusion

Carbon footprint management is no longer merely a component of corporate social responsibility—it is a core business function. For manufacturers, it ensures regulatory compliance, strengthens brand trust, unlocks market opportunities, and enhances cost competitiveness.

In an era where sustainability defines consumer behavior, regulatory landscapes, and supply chain partnerships, manufacturers that lead on carbon management will not only protect their license to operate—but also shape the future of the industry.

Explore more

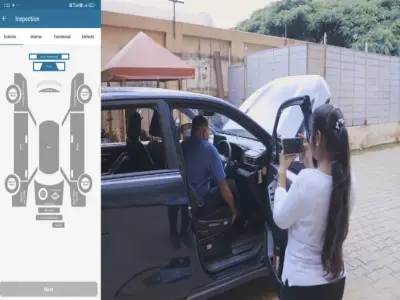

From Paper to Platform: Why It’s Time to Digitize Vehicle Inspections

Explore how digital transformation is revolutionizing manufacturing processes, from IoT integration to AI-powered analytics and smart factory implementations.

The Basics of Vehicle Digital Inspection: What It Is and How It Works

Discover how digital transformation is revolutionizing vehicle inspection processes, improving efficiency, accuracy, and compliance while reducing costs and environmental impact.