Smart Manufacturing and Kaizen: Driving Continuous Improvement with Technology

How Traditional Japanese Principles and Modern Technology Are Transforming the Factory Floor

In the age of Industry 4.0, manufacturers are navigating a complex landscape of rising customer expectations, global competition, and sustainability demands. While digital transformation is reshaping how factories operate, one timeless principle continues to guide operational excellence: “Kaizen”, the Japanese philosophy of “continuous improvement”.

In factories across the world, the pressure to produce faster, cleaner, and smarter is growing. But while automation and AI are changing how we work, the core idea behind great manufacturing hasn’t changed: keep improving, every day. That’s the heart of Kaizen, a simple but powerful philosophy born in Japanese factories, now embraced globally. And when paired with smart manufacturing tools, Kaizen becomes more than a mindset—it becomes a system that helps teams solve problems faster, with data to back them up.

This article explores how Kaizen can be revitalized through smart manufacturing technologies, empowering every worker to drive meaningful changes using real-time data and intelligent systems.

Kaizen: A Philosophy Rooted in Everyday Improvement

The word Kaizen (改善) means “change for the better.” It originated in post-war Japanese manufacturing, most notably within Toyota’s production system, and has since become a global benchmark for operational excellence. Unlike large-scale innovation projects, Kaizen focuses on small, incremental changes that are easy to implement and sustain. It encourages employee-driven improvements, where frontline workers are empowered to identify inefficiencies and suggest practical solutions

Core Principles of Kaizen:

- Continuous, incremental change over time

- Respect for people and their insights

- Standardization of successful practices

- Focus on process, not just outcomes

Simple Steps to Apply Kaizen in Your Factory:

- Observe current workflows and identify waste or inefficiencies.

- Engage teams to brainstorm small, actionable improvements.

- Test and measure the impact of changes.

- Standardize successful practices and repeat the cycle.

Kaizen is not a one-time initiative—it’s a mindset that becomes part of the daily routine.

Smart Manufacturing: The Digital Engine Behind Kaizen

Smart manufacturing refers to the use of advanced technologies, such as IoT, AI, cloud computing, and automation, to create connected, intelligent production environments. These technologies provide real-time visibility and data needed to support Kaizen practices at scale.

How Smart Manufacturing Enhances Kaizen:

-

Real-Time Monitoring: Sensors and IoT devices track machine performance, energy use, and quality metrics instantly.

-

Predictive Maintenance: Sensors and IoT devices track machine performance, energy use, and quality metrics instantly.

-

Digital Dashboards: Visual tools help workers and managers identify trends, anomalies, and improvement opportunities.

-

Automated Reporting: Saves time and ensures accurate documentation of changes and results.

By integrating smart tools into Kaizen workflows, factories can move from reactive problem-solving to proactive, data-driven improvement.

Product-Based Workflow Integration: Making Kaizen Actionable

Here is how DENSO’s three smart manufacturing solutions can support Kaizen in the daily workflows of different user roles:

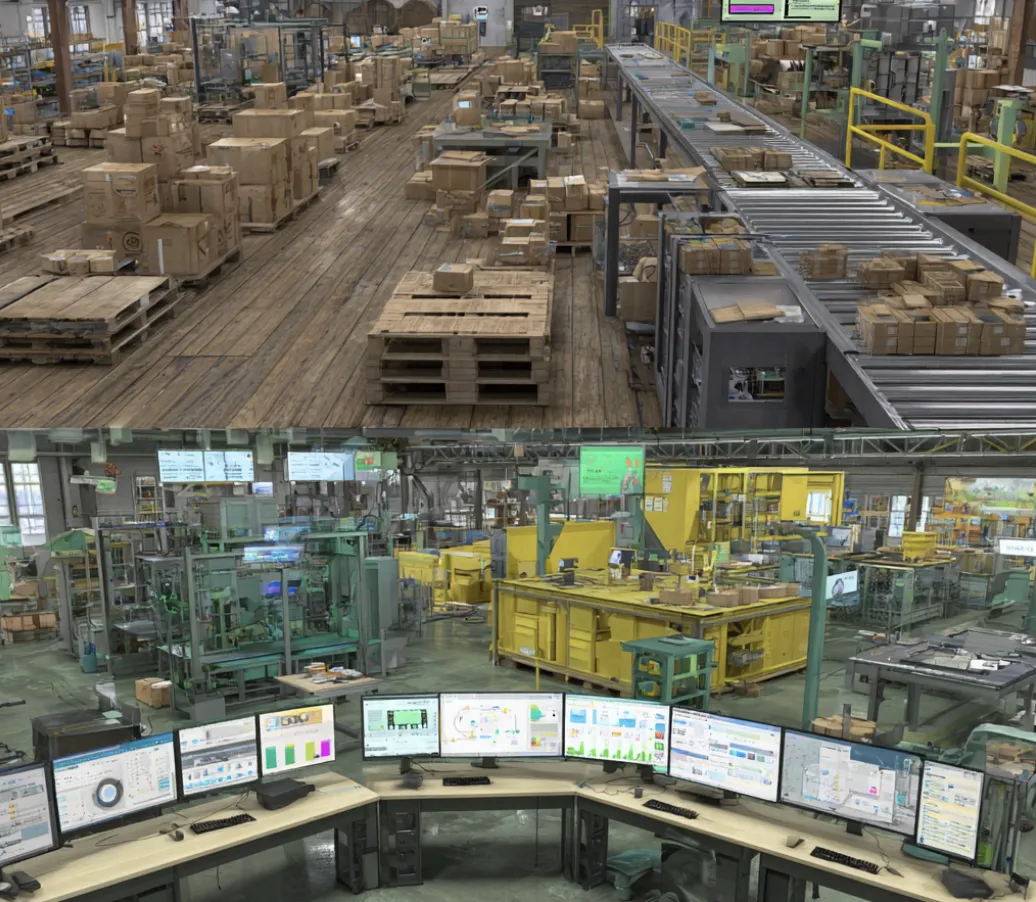

1. Transport & Warehouse Management

Users: Logistics Managers, Inventory Controllers, Supply Chain Heads

Kaizen in Action:

- Optimize delivery routes to reduce fuel consumption and emissions.

- Digitize warehouse operations to minimize errors and improve throughput.

- Track order fulfillment in real time to identify bottlenecks and improve responsiveness.

2. Carbon Footprint Management Platform

Users: Compliance Heads, Sustainability Officers, CEOs & CFOs

Kaizen in Action:

- Monitor Scope 1, 2, and 3 emissions across operations and supply chains.

- Use dashboards to visualize progress and identify high-impact areas for reduction.

- Align with global standards (GHG Protocol, ESG frameworks) and automate compliance reporting.

3. Kaizen IoT

Users: CEOs, Operations Managers, Quality Heads

Kaizen in Action:

- Enable predictive maintenance to reduce downtime and energy waste.

- Monitor machines in real time to optimize performance and reduce variability.

- Automate lean processes and stay audit-ready with built-in compliance tracking.

These tools amplify Kaizen, making continuous improvement faster, more precise, and more scalable.

Why This Matters for Your Factory

Combining Kaizen with smart manufacturing creates a powerful synergy.

- Efficiency gains through targeted, data-backed improvements

- Higher product quality and consistency

- Stronger employee engagement and ownership

- Improved sustainability and regulatory alignment

- Competitive advantage in global markets

Whether you’re a small factory or a large enterprise, this approach helps you stay agile, resilient, and future-ready.

Your Next Step: Start Small, Think Big

You don’t need a full digital overhaul to begin.

Start with one process. Apply Kaizen. Use data. Measure results. Share success. Repeat.

Want to learn how smart manufacturing can support your Kaizen journey?

Explore more

Why Carbon Footprint Management is Becoming a Business Imperative

Manufacturers are at the forefront of the global effort to reduce carbon emissions. What was once a voluntary sustainability initiative has evolved into a non-negotiable business requirement. Today, managing carbon emissions is not optional—it is a strategic necessity that directly influences market access, brand equity, and long-term business resilience.

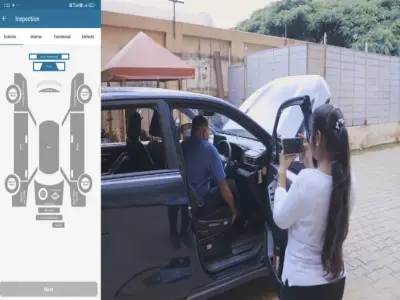

The Basics of Vehicle Digital Inspection: What It Is and How It Works

Discover how digital transformation is revolutionizing vehicle inspection processes, improving efficiency, accuracy, and compliance while reducing costs and environmental impact.

How Carbon Footprint Management Drives Corporate Financial Performance

How Carbon Footprint Management Drives Corporate Financial Performance